Story about cement factory and letter

The letter that was never published

My grandfather got a job at the “Split” cement factory in Majdan. As he came from Gorski Kotar, the owner of the factory gave him a house to live in. He paid for electricity, water, firewood, and a ‘housekeeper’ to help around the house. My dad and uncles were born there. They always felt the people of Majdan.

Fate brought II. The World War in which my grandfather was shot, so my grandmother was left alone with four sons. Dad joined the partisans at the age of 14 to avoid being shot. After the war, he received scholarships from the factory and continued his education. He graduated from the Faculty of Mechanical Engineering and got a job in a factory. After that, he went to Omiš as the director of the cement factory “Renko Šperac” and in 1969 he returned to the position of director of “10. August” in Maidan.

As a little girl, he took me to the factory on non-working Saturdays (at that time, we worked two Saturdays a month, and two were free). He had to walk through the plants, talk to the workers, make sure that everything is working as it should. I found the furniture in his office fascinating. The table and cupboards were from the time when the owner of the factory was Stock. Dad was especially proud of that fact. When he left that job for another, his successor threw out all the wooden furniture and bought a new one made of chipboard.

In the following, I will copy his letter to “Slobodna Dalmacija” (never published), which he wrote on the occasion of the closing of the factory by the new owners two months before it celebrated its 100th anniversary:

The factory did not only produce cement but also had another, constant influence on this region. Other factories had that too. Most often, they shouted at the factories for polluting, and they forgot all the other benefits of those factories.

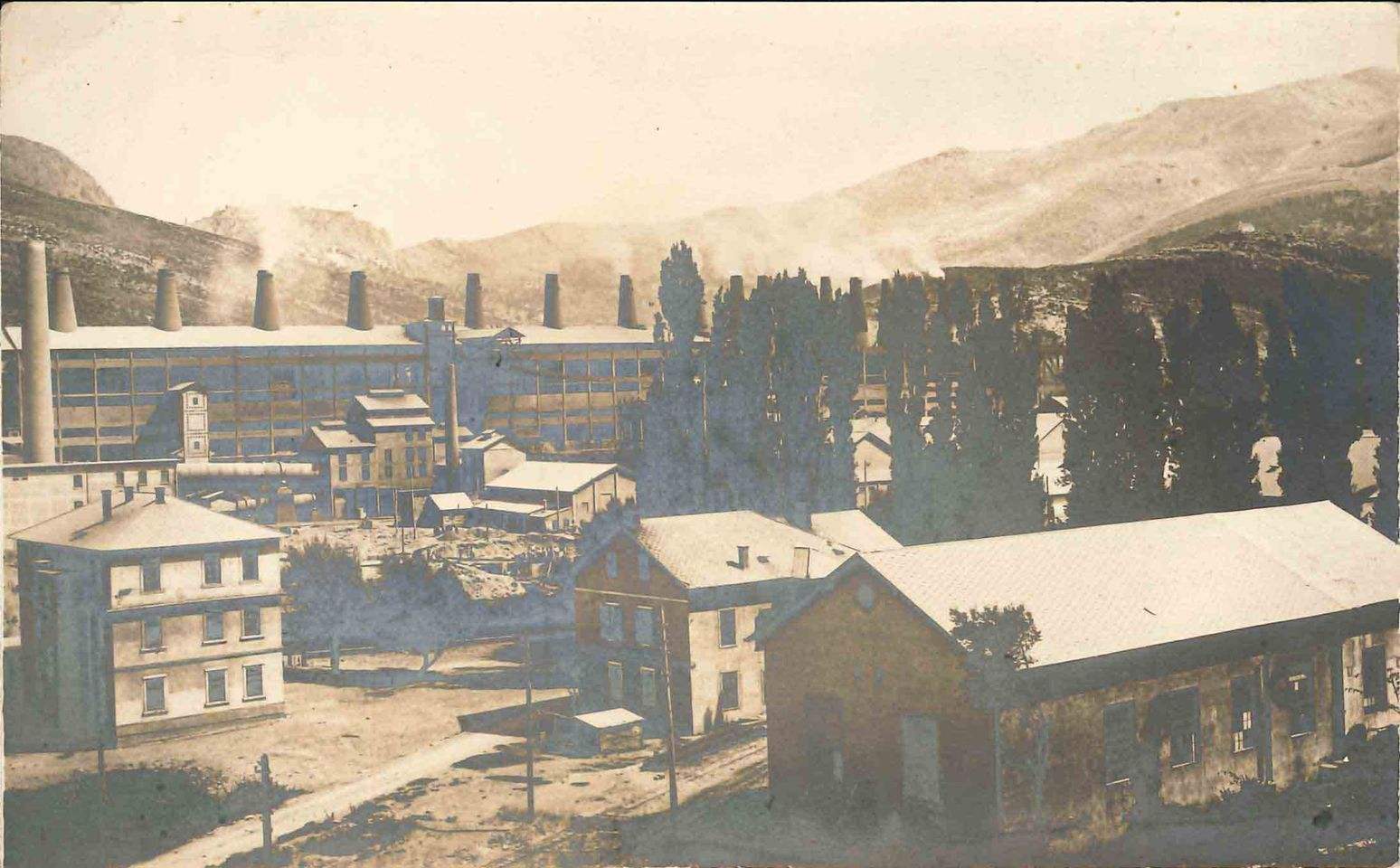

1908 The company “Split” a.d. was founded. to build a cement factory in the area of Solin. It was already known that in that area there was raw material marl or tupina as we called it. It is petrified clay. Mixed with limestone and fired at a high temperature, it produces a hydraulic binder good for construction. That would be Portland cement. It was named after the city of Portland in England. There, an engineer found that road dust, generated by carts, mixed with limestone and baked made a good binding agent for construction.

Mr. Stock, seeking permission to build a factory, was granted permission with some conditions by the municipality of Split. They will pay 150,000 dinars as a guarantee that the factory will work successfully. If the factory would not work successfully, the field must be restored to the condition it was in before construction. He undertook to employ labor from this area (Solina, Kaštela, and Split). He can hire foreigners, only experts who are not here. Interestingly, he employed only and mainly Slavs: Russians, Czechs, Slovaks, Slovenes, Trieste Croats and Slovenes, and Jews. The Jews were from the territory of the Kingdom of Yugoslavia. Namely, Mr. Stock was Jewish.

When we later employed people from Klis, Solin, Mravince, Kučine, Vranjic, and Split, they used to criticize us for hiring only our people!? But they forgot and didn’t know that these people gave their lands for the needs of the factory, and according to the municipality’s decision, we were obliged to employ these people. The factory employed from 700 to 1000 workers. Later, by modernizing the factory, we employed around 400. Today’s owners tried to prove that the factory can work even without workers. So for a while, she worked with only 28 workers in 3 shifts. At that time, the fuel oil escaped into the Jadro river. It was said that the human factor is to blame. Recently, about 80 workers have been working. And they will be fired. The union official, in the newspaper, said that he had nothing to say.

When the new owners took over Dalmacijacement, they fired about 4,000 workers. Among them, about 350 engineers and technicians. Here’s a question for the union: why did you fire the engineers and technicians? Couldn’t they maintain the factories like they did before? If there were more of them, they could work for third parties in the workshops, as they did before. Each factory had a mechanical and electronic workshop. We also had a gray iron foundry.

When Mr. Stock asked for a concession to use the waters of the Jadro river, he got a permit with the provision that Split would receive electricity. In 1913 and 1914, he built a hydroelectric plant at the source of the Jadro River. These were two generators of 500 kW each. Below was a “small power station” built by Mr. Vidović, with a power of 150 kW. It still had a diesel power plant with two 400 kW generators. In 1928, as part of the rotary kilns, he built a thermal power plant with a capacity of 2000 kW.

“Split” a.d. and “Dalmatia” from Dugi Rat founded an electrical company. Since there was no transmission line to Split, “Split” a.d. bought a locomotive (steam engine) with a generator, which was located on the waterfront and temporarily, until the construction of the transmission line to Split, provided lighting to the city of Split.

The first furnace was lit on February 2, 1909. So now it is already the 100th anniversary of successful work. Yes, this is not exactly true, because the owners did not wait for the factory to live for 100 years and then shut it down, but what is there is. These owners shut it down two months earlier. The factory had 64 furnaces of the Dietzsch (dic) type. It had 16 chimneys. There were 4 stoves under each chimney. These were vertical furnaces. In 1928, two rotary furnaces with gas recovery were built, i.e. the thermal power plant was part of the furnace. The gases were used to generate electricity. After World War II, 3 more Gruber-type vertical kilns were built, and in 1971 a new kiln with a capacity of 1,000 tons per day of clinker with modern raw material preparation. The stove was manufactured in Czechoslovakia under license from the German company Humboldt.

Cement production was 620,000 t per year. Capacity utilization was 92%. The furnace was designed to produce 950 tons per day, and it produced an average of 1,100 tons. This was achieved through the very conscientious work of workers and experts. It has rarely happened in the world that a machine produces more than it was designed for.

The factory had very good protection at work. We had our clinic with a doctor and a nurse, a medical technician, and an occupational safety technician. The workers had protective equipment, a hot meal, transportation from home to work, and vice versa. We had no occupational diseases. The biggest scourge was alcoholism. We had a successful society of treated alcoholics. In this asbestos dust campaign, I didn’t notice anyone asking the doctors of our factories. It is not true that they were forbidden to talk about workers’ illnesses. It is easy to determine the mortality of people in this area and from which diseases people die. Is it more than elsewhere in Croatia?

Workers acquired professional knowledge in factories. They learned trades, acquired professional qualifications, and received scholarships for their studies. They have obtained master’s degrees and doctorates.

Culture was also represented. We had a workers’ home with a cinema hall with a stage and a library with 2000 books. The librarian was one worker, Ante Perković, who read all 2000 books! We also had an acting group led by Vjera Juretić – an employee. Chess section – the embryo of today’s chess society in Mravince. Mrs. Desa Grizogono and director Eng. Josip Morpurgo made sure that the home was a little different from the others. Leading Croatian painters painted the walls of that home. Unfortunately, the home was set on fire and burned down. Some unscrupulous journalist wrote on that occasion that an “old” home had burned down. This can also be attributed to the negligence of the institution in the preservation of the cultural heritage of the municipality of Split, which does not have that home in its records and did not warn the owners to preserve it. The factory also helped the brass band from Klis. The factory workers mostly played the music.

The factory also helped with sports. Workers competed through workers’ sports games. The successes of our shooters are well known. Today’s shooting club in Solin was created from the shooting party of our workers. They had republican and federal results, just as the Solin archers have today. The factory helped build seven football fields. She helped the football and swimming clubs. Like other sports. At that time, Dalmacijacement gave about 5 million dinars to sports.

It built and distributed around 2,000 apartments to workers. Our factory gave 7 apartments to doctors. I must say, to understand this, that Dalmacijacement employed about 5,000 workers. I think that companies that have been working for 100 years should not go into oblivion—factory Sv. Kajo turned 100 years old in 2004, and the Sv. Jure will be 100 years old in 2012.